UV ink is an environmentally friendly, green and sustainable ink. Compared with traditional solvent inks, UV inks have the advantages of good gloss and strong stereoscopic effect. Especially in terms of drying, UV inks are rapidly cured under the irradiation of UV curing light sources, which avoids the long drying cycle of traditional solvent inks and the occupation of curing devices. Disadvantages such as large area.

With the rapid development of the printing industry, the green environmental protection issues of printing enterprises have also attracted public attention. High efficiency, cost saving, energy saving and environmental protection have become the main goals of printing enterprises. In recent years, the use of UV inks has been increasing, and the printing speed needs to be continuously improved, and curing equipment is one of the limiting factors.

The traditional printing curing light source is mainly UV mercury lamp or halogen lamp, which has the disadvantages of high energy consumption, large heat, slow start-up and short service life. UVLED curing light source has become a new development trend. The commonly used curing wavelengths of UVLED are 365nm, 385nm and 395nm, with low heat, no ozone generation, energy saving and environmental protection, single-wavelength light source concentration, high printing ink curing efficiency, and safer and more reliable use.

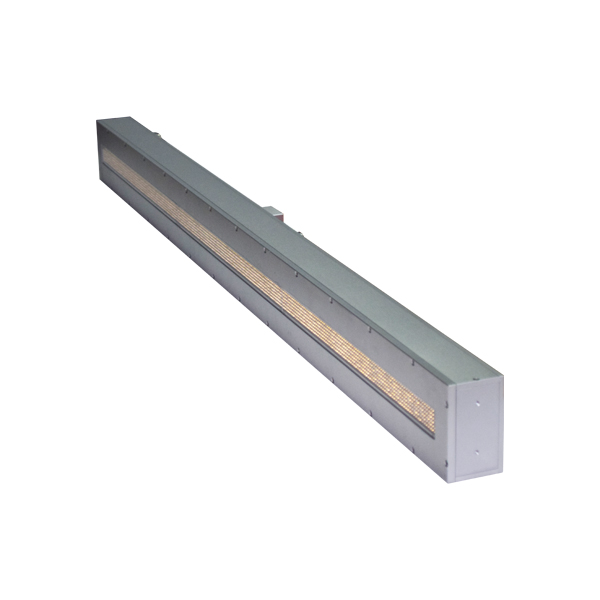

With the rapid development and mature application of UVLED curing technology, many printer manufacturers have also launched relatively advanced UVLED printer products according to their own and market needs. However, the investment cost of new equipment is usually high. Enterprises can modify the UVLED curing system on the existing printing production line, which not only reduces the cost, but also improves the technical level of the equipment. The UVLED light curing device developed and produced by Height-LED is small in size and easy to install, which can ensure the production quality, greatly improve the production efficiency and shorten the production cycle.

As a manufacturer of UVLED curing equipment, Shenzhen Height-LED is committed to providing customers with a complete set of curing solutions. The products have standard products and can also customize products according to customer needs. If you have UVLED curing requirements, you can contact online customer service, or call for consultation and exchange.