Now, many manufacturing industries have begun to attach importance to environmental protection, and the printing ink industry is no exception. At present, most printing factories use relatively green and environmentally friendly UV printing inks.

However, UV ink curing machine equipment is mainly divided into mercury lamps and UVLED light curing machines. Because mercury lamps need to be replaced regularly, the higher irradiation temperature is not conducive to packaging and printing. Therefore, many manufacturers choose to use cold light sources, which have faster curing and longer service life. Long UVLED light curing machine.

The advantages of UVLED curing machine for UV printing ink curing are as follows:

1. The UVLED light curing machine has a built-in microcomputer automatic control system, which is intelligent and convenient to use;

2. The unique light path design scheme makes UV light irradiation more uniform; there are program control systems with multiple application modes, which can meet the needs of various processing techniques;

3. High light intensity. The UVLED curing machine with special coding has the characteristics of high light intensity, which can effectively improve the production speed and yield rate;

4. Environmental protection, energy saving, low consumption, the energy consumption of UVLED curing machine is only 80% of traditional mercury lamp;

5. Each illuminating lamp head of the UVLED light curing machine can be used at the same time or separately, which is more flexible to use and saves product costs;

6. UVLED can convert 15% to 30% of the input electric energy into usable UV light, without UVC wavelength and infrared wavelength harmful to human body, without thermal radiation, and can be used for heat-sensitive materials;

7. The light wavelength, light intensity, curing irradiation size, curing speed, etc. of the UVLED light curing machine can be configured according to actual needs;

8. Water cooling heat dissipation, the machinery and equipment can conduct good heat dissipation during operation, to ensure the long service life of the machinery and equipment chips, and there will be no overheating of the illuminating lamp;

9. The UVLED curing machine does not contain harmful substances such as mercury and heat radiation, making it more environmentally friendly and safer.

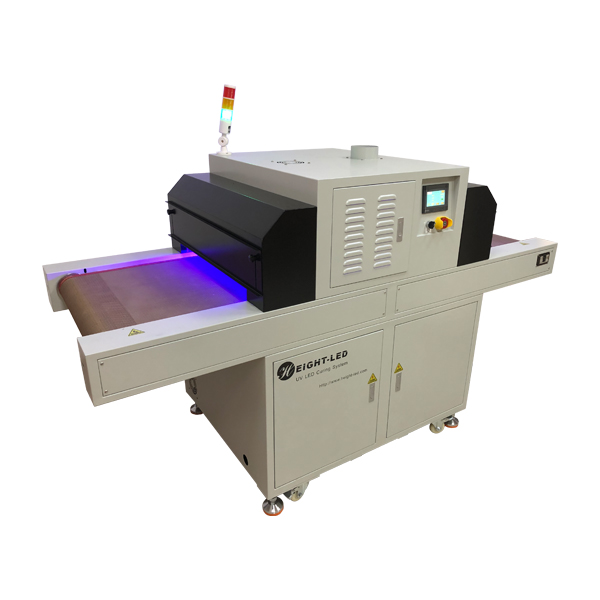

Shenzhen Height-LED specializes in the production of uvled curing equipment, and can customize suitable uvled curing systems for customers. Welcome to consult.