Since the birth of UVLED light curing, after years of development, it has been widely used in industries such as optics,

industry, medical treatment, printing, new energy, optical communications, and electronic assembly. Among them, the

field of optical film is also an industry that has attracted attention in recent years.

According to network data, optical film, as the core hardware of smart TV display, benefited from the smart TV boom,

and the market demand for optical film will be released quickly and continue to be strong. Based on the requirements for

environmental protection, as well as the characteristics and special applicability of the optical film itself, the market has

increasingly higher requirements for the optical film coating industry. The UV curing process has also changed from

traditional mercury lamps to more environmentally friendly and efficient UVLED light. Curing equipment.

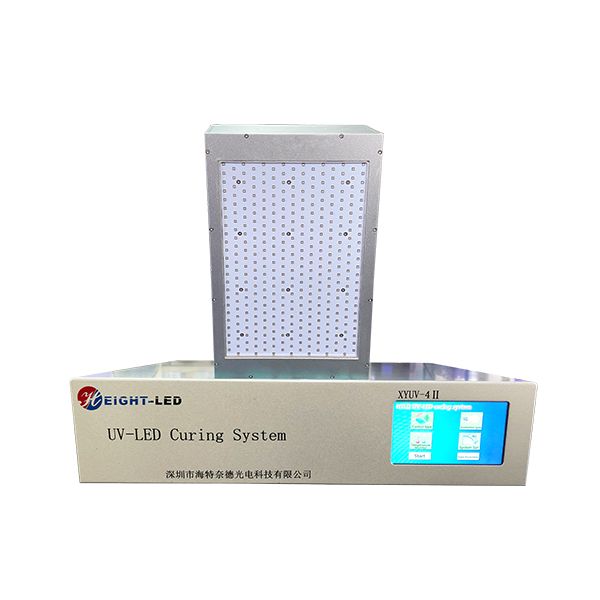

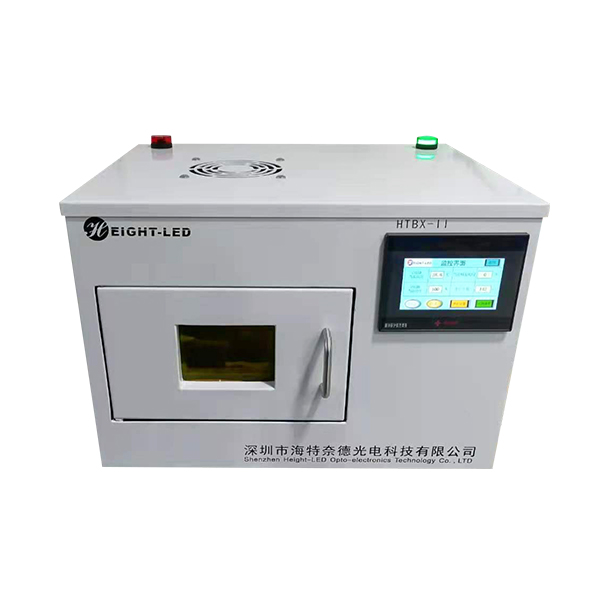

Compared with traditional UV mercury lamps, UVLED light curing equipment has significant advantages:

1. The UVLED curing light source is a cold light source, which will not cause working thermal stress and deformation, and

will not affect the product performance due to high temperature. It is suitable for the curing of heat-sensitive materials.

2. The service life of the UVLED curing light source can reach 20,000 hours, which is 10 times that of the traditional mercury

lamp, and there is no need to preheat before use, and it can be used as soon as it is turned on, saving time.

3. Compared with mercury lamps, the power consumption of UVLED light curing equipment will save up to 70% and save costs.

4. Each independent unit of Hetnaide UVLED light curing equipment can be independently controlled, and the light power

intensity can be adjusted from 1 to 100%, which can be adjusted according to actual needs, which not only saves energy,

but also effectively controls production capacity.

5. Height-LED UVLED light curing equipment is a pollution-free product, does not contain mercury pollution, is environmentally

friendly, and meets the requirements of environmental protection policies.

At present, the optical film industry tends to choose UVLED light curing equipment in the use of UV lamps. Height-LED

will also actively cooperate with optical film manufacturers to develop suitable curing equipment to contribute to the

development of the optical film industry and environmental protection and energy saving.