As a new curing method, UVLED curing machine has gradually replaced UV mercury lamp. So, what is the difference between curing UV glue using UVLED curing machine and UV mercury lamp? Height-LED UVLED curing machine manufacturer, let me share with you the difference between these two curing methods of UV glue.

deep curing

In terms of the time required for UV glue curing, it may be faster to use a UV mercury lamp, because the UV mercury lamp has a high power and a fast output light intensity, so the curing speed is fast. Compared with UV mercury lamp, UVLED curing machine can achieve better deep curing effect under the condition of consistent glue sizing thickness and irradiation height.

curing uniformity

The uniform curing of UV glue refers to whether the curing degree of the entire adhesive layer is consistent from the outside to the inside after sizing, and whether the same curing effect can be achieved as a whole. In this regard, it is more suitable to choose UVLED curing opportunities than UV mercury lamps. The reason It is the UV mercury lamp along the length of the lamp tube, the luminous intensity at both ends is weaker than that of the middle part, it cannot emit light uniformly, and it cannot achieve uniform irradiation of flat objects, so that the light intensity absorbed by the cured material is different, which affects the overall curing effect, especially the large curing area. The UVLED curing machine has the same light source for each lamp bead, consistent wavelength and high concentration, which makes the UV glue curing more uniform.

product structure

In terms of product structure, what should be paid attention to is the heating situation. UV mercury lamps will generate infrared rays and emit a lot of heat, which is easy to cause damage to heat-sensitive substrates. The UVLED curing machine emits a cold light source, which can effectively avoid the shrinkage and deformation of the substrate due to overheating. Therefore, the unheatable electronic components or materials that are easily deformed by heat should be cured with a UVLED curing machine.

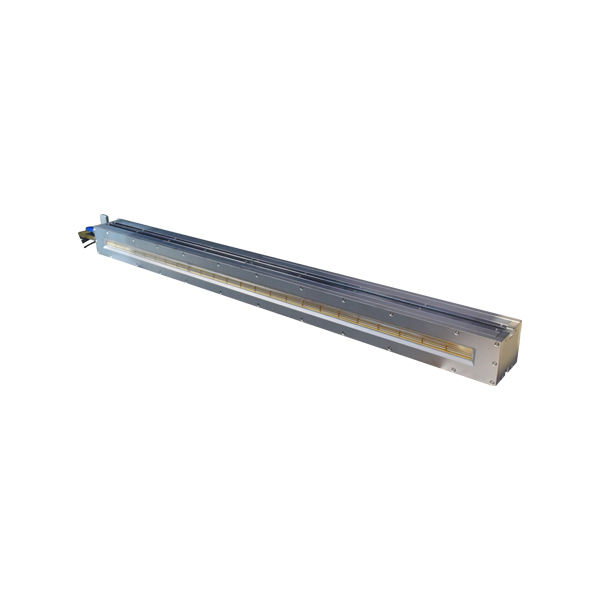

Shenzhen Height-LED specializes in the production and sales of UVLED point light sources, UVLED line light sources, UVLED surface light sources, UVLED curing machines, UVLED curing ovens, dispensing, spraying, spraying, automation equipment and other products, with a professional team and rich experience . We can customize suitable UVLED curing system for customers, welcome to consult.